Manufacturing Support & Drafting Services

Our Manufacturing Support & Drafting services ensure that your product is ready for seamless production. From creating detailed 2D & 3D manufacturing drawings to preparing GD&T and Bill of Materials (BOM), PACECAD provides everything you need for efficient, error-free manufacturing.

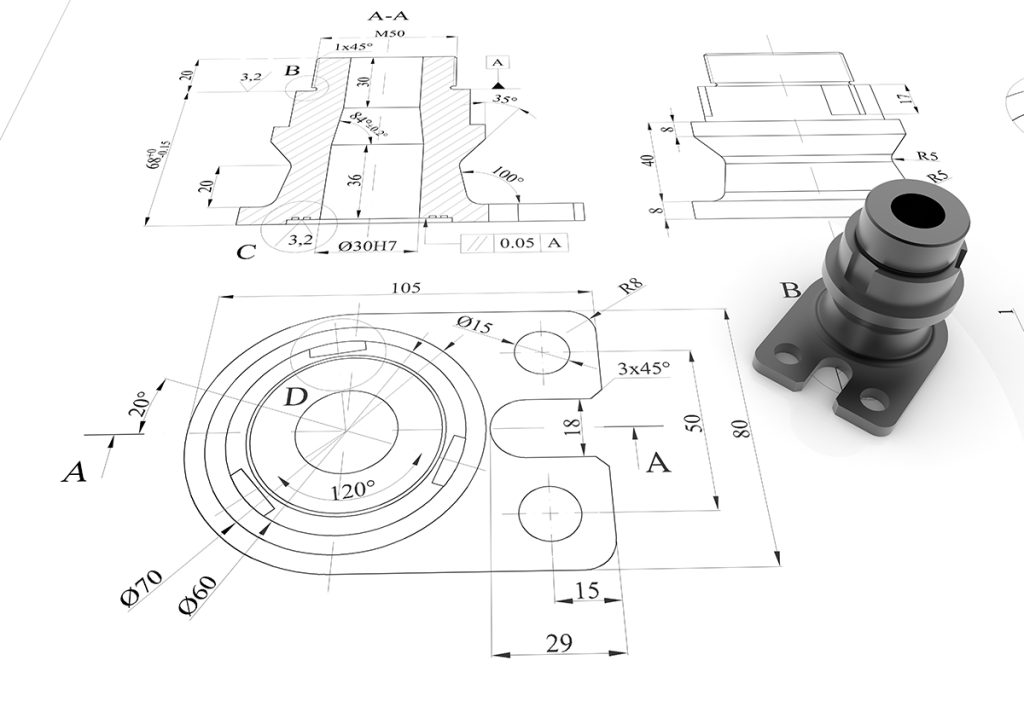

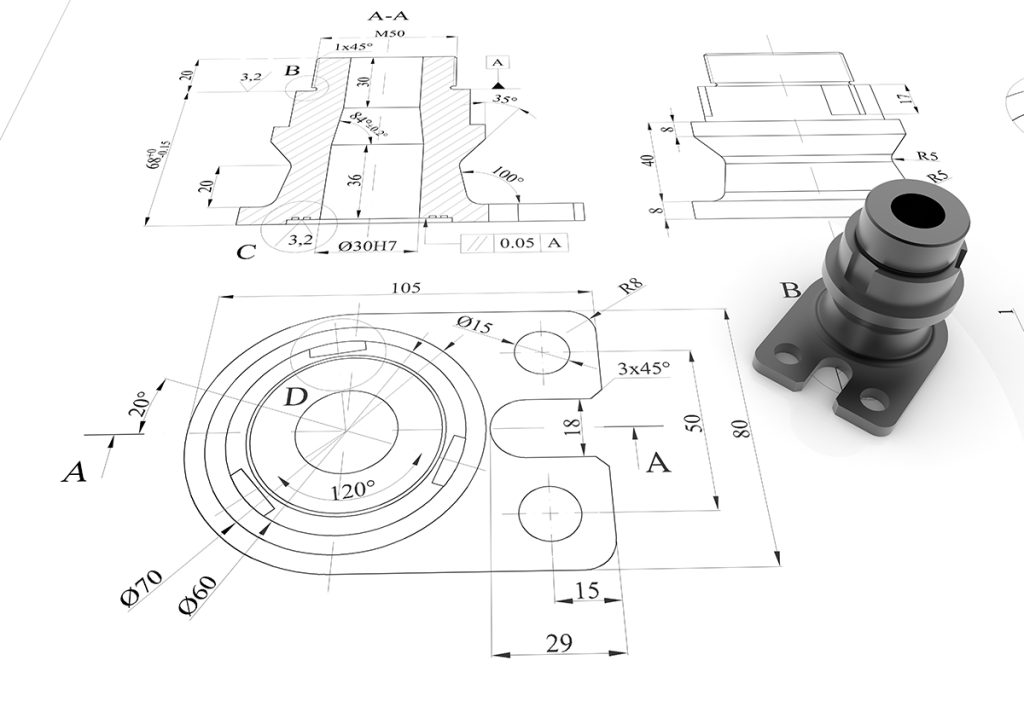

2D & 3D Manufacturing Drawings

We create highly detailed and precise 2D & 3D drawings that outline every specification for manufacturing. These drawings serve as the backbone for production, helping to eliminate any ambiguity and ensuring that your product is built to the exact standards required.

- 2D Drafting: Clear, dimensioned drawings for manufacturing.

- 3D Models: Fully detailed, ready-to-manufacture 3D CAD files.

- Cross-Functional Collaboration: Our designs align with both engineering and production teams to avoid miscommunication.

Our drawings include all essential views, dimensions, and tolerances, helping to streamline production and reduce the risk of errors.

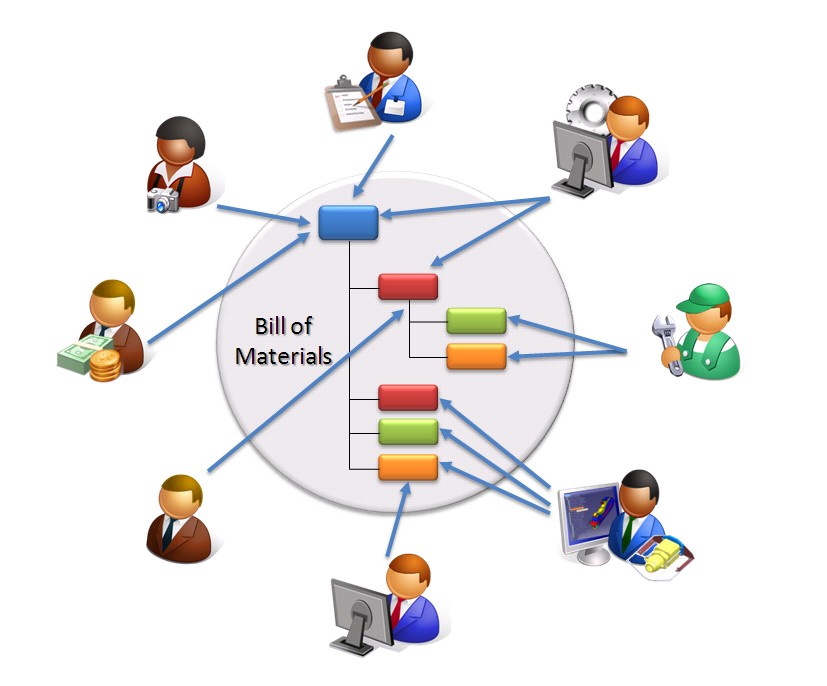

GD&T & Bill of Materials (BOM) Preparation

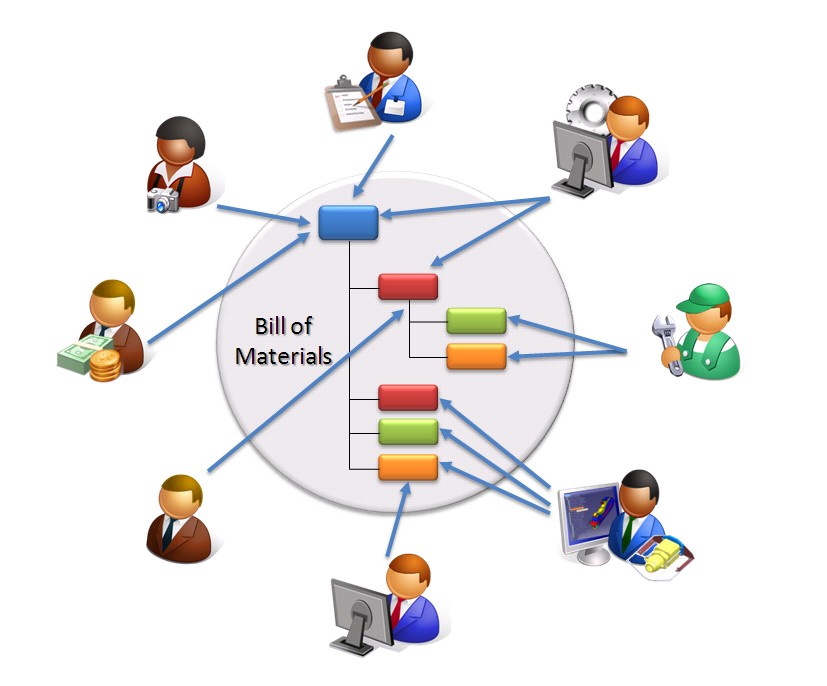

Geometric Dimensioning and Tolerancing (GD&T) and Bill of Materials (BOM) preparation are crucial in ensuring manufacturing accuracy and quality control. We create GD&T specifications that guarantee the design meets critical tolerances, and our BOM outlines every material and component necessary for production.

- GD&T: Ensuring design intent is fully realized through precise tolerance definitions.

- BOM: A comprehensive list of materials, parts, and components required for manufacturing.

- Streamlined Production: Minimize the chance for errors by providing clear, actionable instructions.

We use Geometric Dimensioning and Tolerancing (GD&T) to specify design tolerances that ensure your product’s functionality and manufacturability. Our team also prepares detailed Bill of Materials (BOM) that outlines all materials and components needed for production, facilitating smoother communication between design and manufacturing teams.

Sheet Metal, CNC, and Plastic Part Designs

PACECAD specializes in designing components for sheet metal, CNC machining, and plastic molding. Our designs are fully optimized for specific manufacturing processes, ensuring that parts are durable, efficient, and cost-effective.

- Sheet Metal Designs: Creating intricate, durable metal parts with the right tolerances and material specifications.

- CNC Machining: High-precision designs for parts made using CNC machines.

- Plastic Molding: Expert designs for injection-molded components with a focus on manufacturability.

Manufacturing Support & Drafting Services

Our Manufacturing Support & Drafting services ensure that your product is ready for seamless production. From creating detailed 2D & 3D manufacturing drawings to preparing GD&T and Bill of Materials (BOM), PACECAD provides everything you need for efficient, error-free manufacturing.

2D & 3D Manufacturing Drawings

We create highly detailed and precise 2D & 3D drawings that outline every specification for manufacturing. These drawings serve as the backbone for production, helping to eliminate any ambiguity and ensuring that your product is built to the exact standards required.

- 2D Drafting: Clear, dimensioned drawings for manufacturing.

- 3D Models: Fully detailed, ready-to-manufacture 3D CAD files.

- Cross-Functional Collaboration: Our designs align with both engineering and production teams to avoid miscommunication.

Our drawings include all essential views, dimensions, and tolerances, helping to streamline production and reduce the risk of errors.

GD&T & Bill of Materials (BOM) Preparation

Geometric Dimensioning and Tolerancing (GD&T) and Bill of Materials (BOM) preparation are crucial in ensuring manufacturing accuracy and quality control. We create GD&T specifications that guarantee the design meets critical tolerances, and our BOM outlines every material and component necessary for production.

- GD&T: Ensuring design intent is fully realized through precise tolerance definitions.

- BOM: A comprehensive list of materials, parts, and components required for manufacturing.

- Streamlined Production: Minimize the chance for errors by providing clear, actionable instructions.

We use Geometric Dimensioning and Tolerancing (GD&T) to specify design tolerances that ensure your product’s functionality and manufacturability. Our team also prepares detailed Bill of Materials (BOM) that outlines all materials and components needed for production, facilitating smoother communication between design and manufacturing teams.

Sheet Metal, CNC, and Plastic Part Designs

PACECAD specializes in designing components for sheet metal, CNC machining, and plastic molding. Our designs are fully optimized for specific manufacturing processes, ensuring that parts are durable, efficient, and cost-effective.

- Sheet Metal Designs: Creating intricate, durable metal parts with the right tolerances and material specifications.

- CNC Machining: High-precision designs for parts made using CNC machines.

- Plastic Molding: Expert designs for injection-molded components with a focus on manufacturability.