Services We Offer

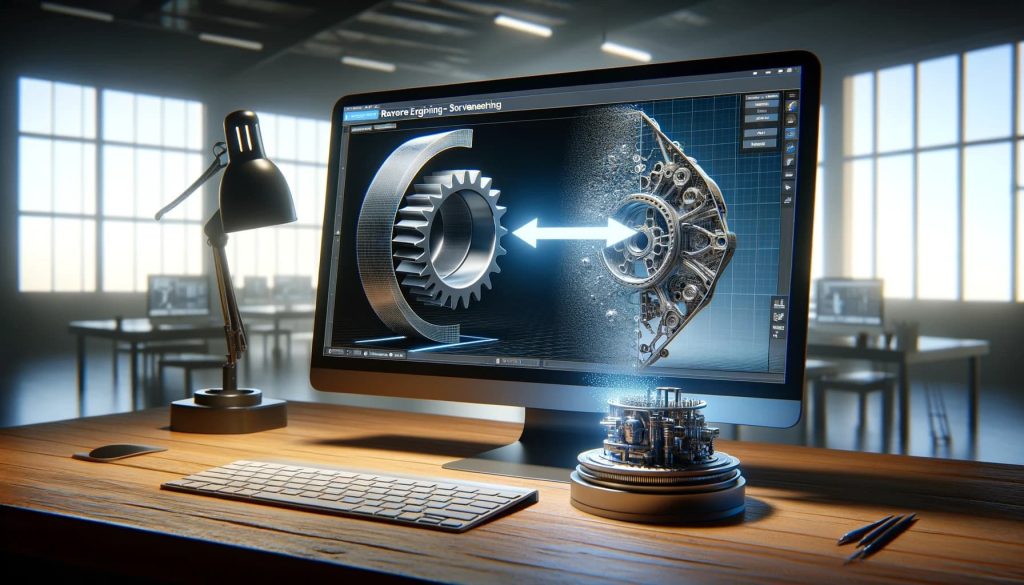

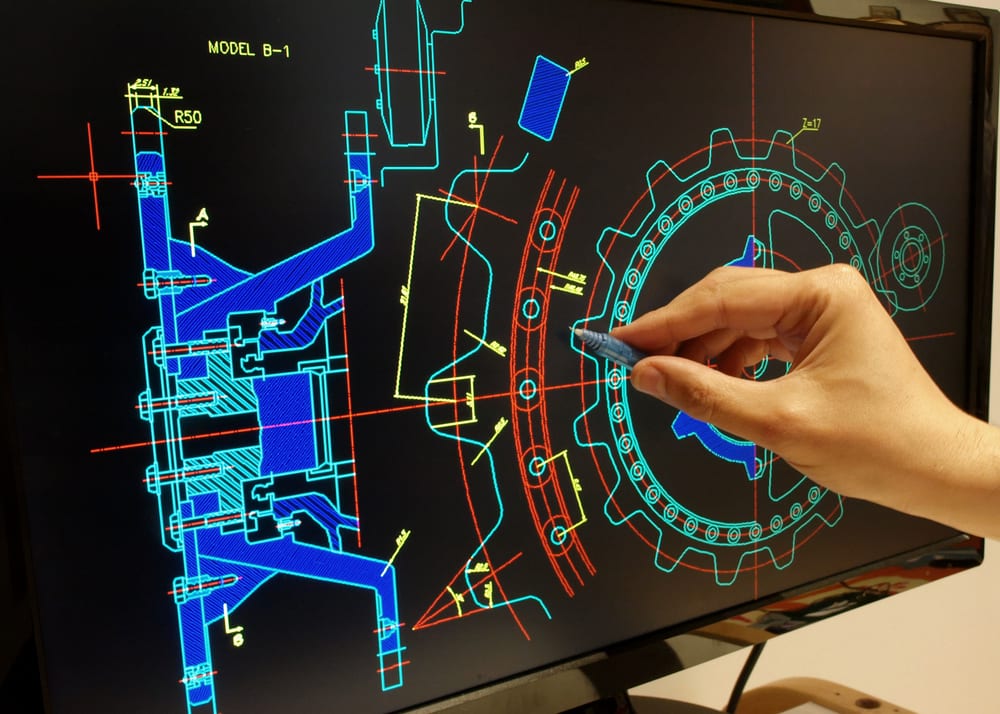

Product Design & Development

- We turn ideas into manufacturable designs with advanced 3D CAD modeling, reverse engineering, and prototype development. Whether it’s an early-stage concept or an improvement to an existing product, we ensure feasibility and functionality.

- 3D CAD Modeling (SolidWorks, AutoCAD, Fusion 360) Conceptual Design & Development

- Reverse Engineering & Design Optimization Prototyping & Feasibility Studies

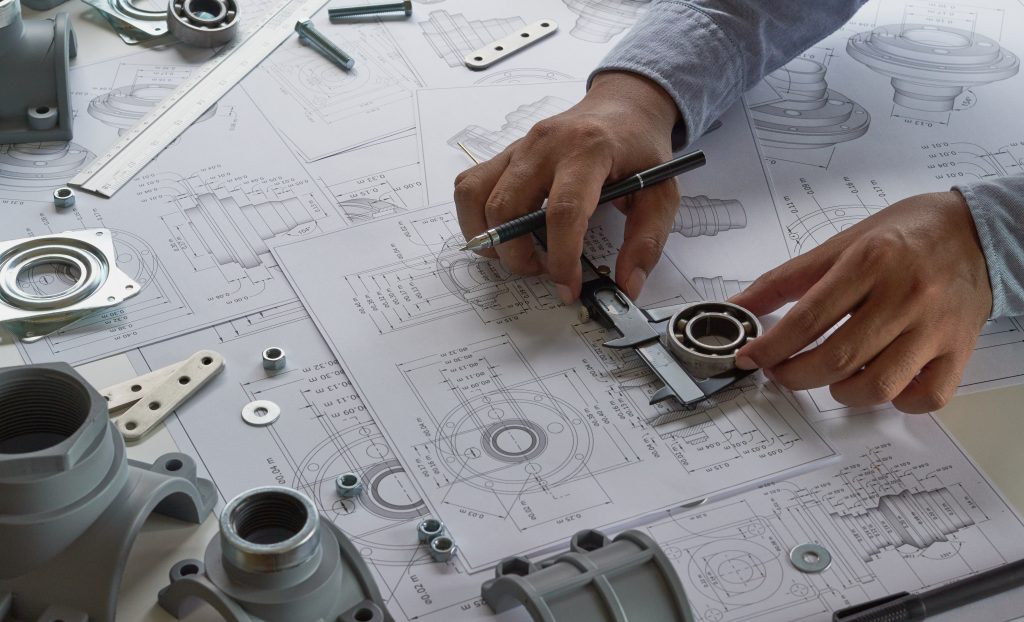

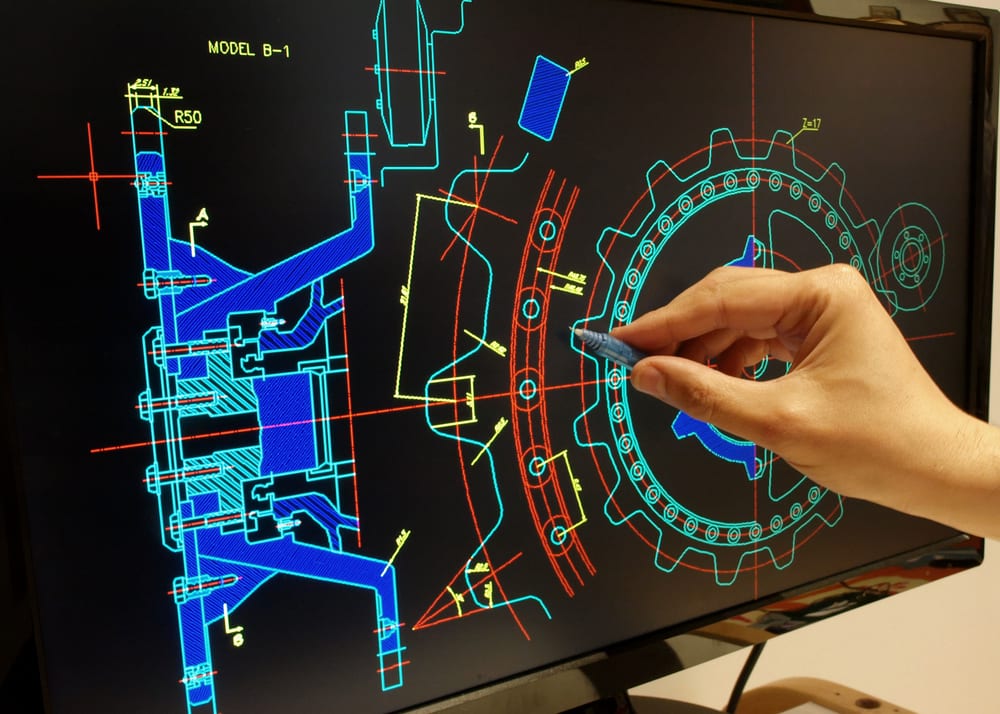

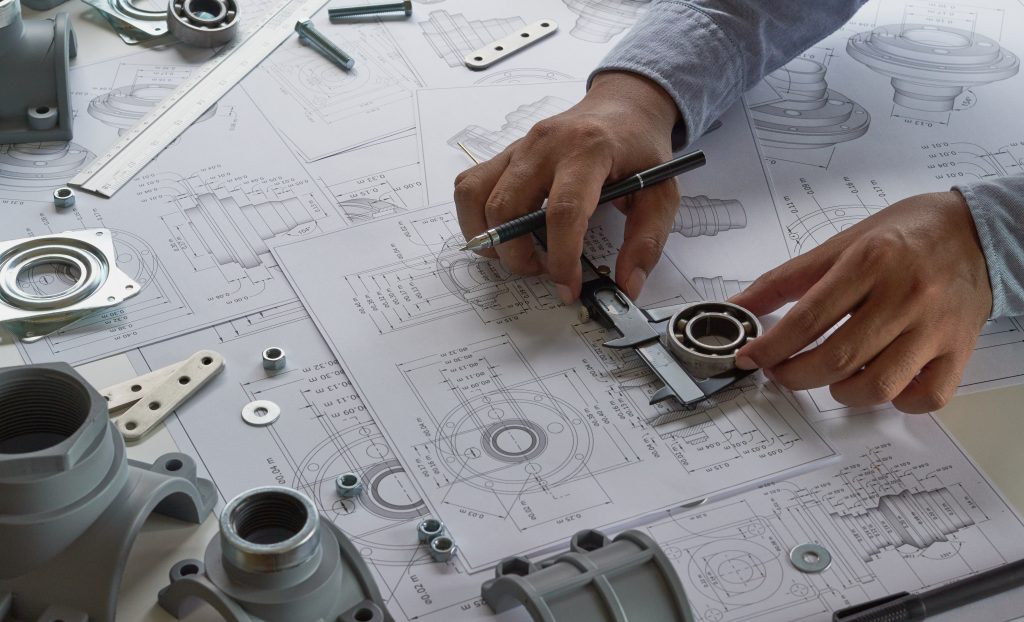

Manufacturing Support & Drafting

- Manufacturing requires precise documentation and specifications. We provide high-quality 2D manufacturing drawings, GD&T, and BOM preparation, ensuring smooth production workflows.

- 2D Drafting & Manufacturing Drawings GD&T Application for Tolerancing BOM

- Preparation & Part Numbering Sheet Metal, Plastic, and CNC Machining Designs

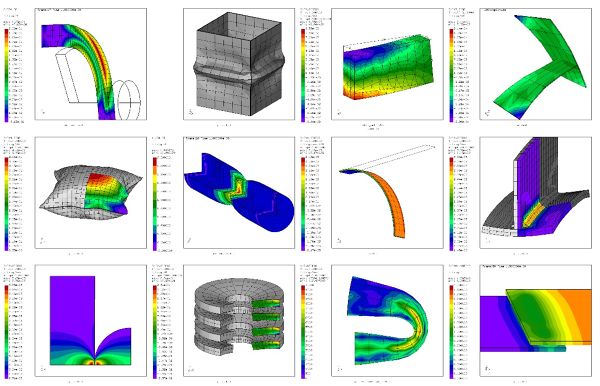

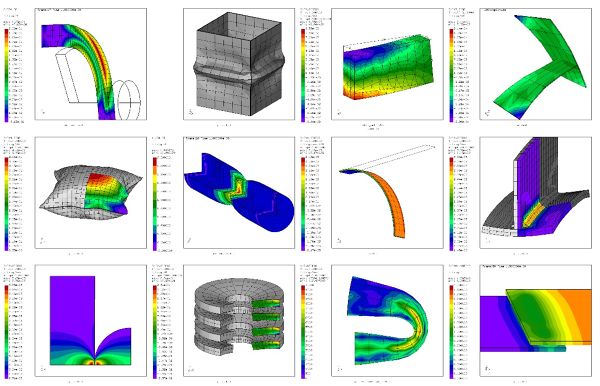

Finite Element Analysis (FEA) & Simulation

- Structural integrity and performance validation are key to product success. Our advanced FEA simulations help identify weaknesses, optimize designs, and enhance durability.

- Static Structural Analysis – Strength and load-bearing assessments Thermal Analysis – Heat transfer simulations for optimal performance Vibrational & Modal Analysis – Ensuring stability under dynamic conditions Failure Analysis & Design Optimization

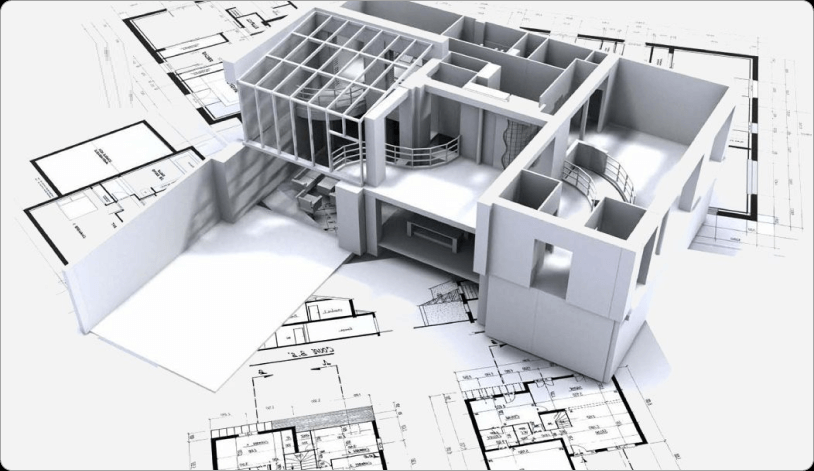

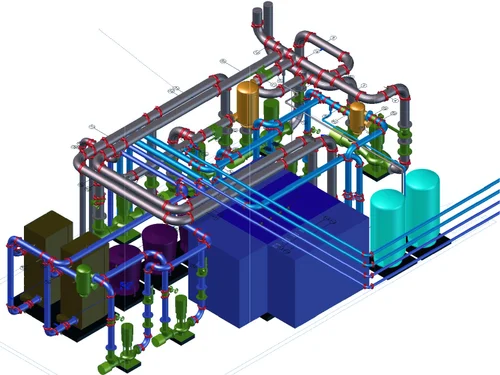

CAD Design & 3D Modeling

Comprehensive 2D and 3D CAD modeling for precision engineering.

Concept development with detailed technical drawings and documentation.

Design optimization to enhance efficiency, performance, and manufacturability.

Assembly modeling and interference analysis to ensure seamless integration.

Finite Element Analysis (FEA) & Computational Fluid Dynamics (CFD)

Structural analysis to assess stress, strain, and load-bearing capacity.

Thermal and dynamic simulations to ensure product reliability.

Fluid flow analysis (CFD) for aerodynamics and heat transfer optimization.

Failure prediction modeling to enhance safety and performance.

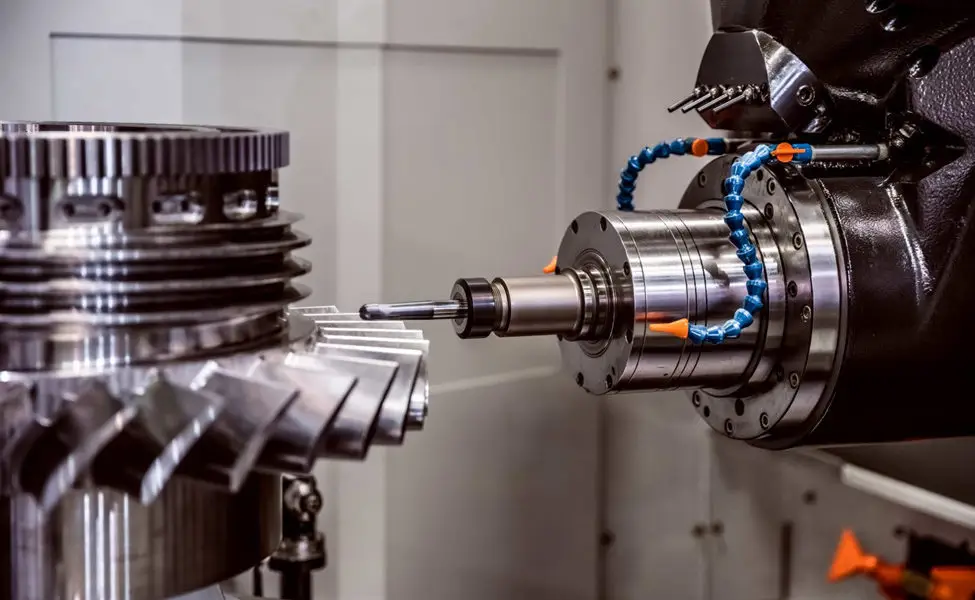

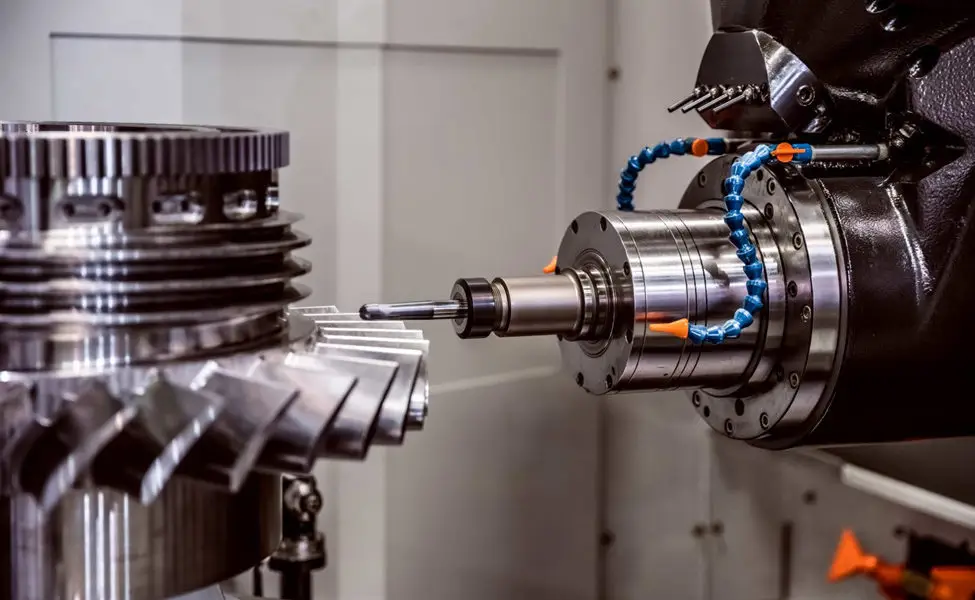

CNC Machining & Precision Manufacturing

High-precision CNC milling, turning, and grinding for complex geometries.

Prototyping to full-scale production with scalable manufacturing solutions.

Material selection expertise for durability and lightweight engineering.

Stringent quality control ensuring dimensional accuracy and consistency.

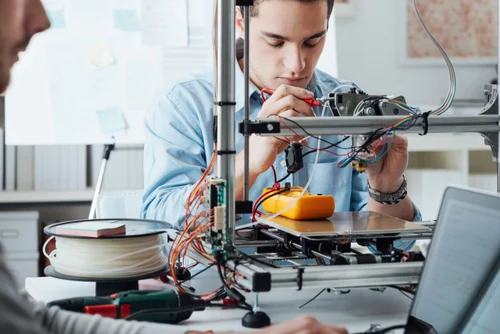

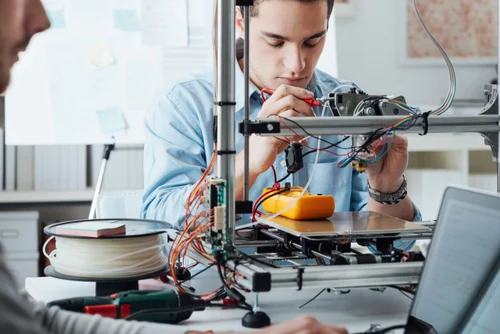

Prototyping & Product Development

Rapid prototyping using 3D printing, CNC machining, and injection molding.

Functional and ergonomic testing for performance validation.

Iterative design refinement for enhanced product efficiency.

End-to-end product development support, from concept to production.

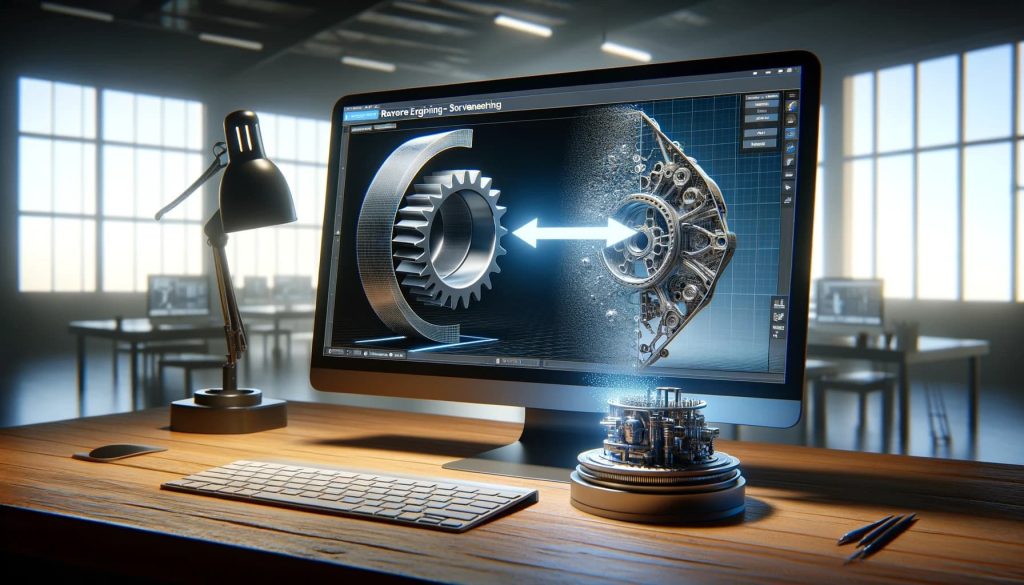

Reverse Engineering & Legacy Part Digitization

High-precision 3D scanning and CAD modeling for component replication.

Digitization of obsolete parts for modern manufacturing applications.

Performance enhancement of existing designs through engineering analysis.

Seamless integration of reverse-engineered components into new product lines.

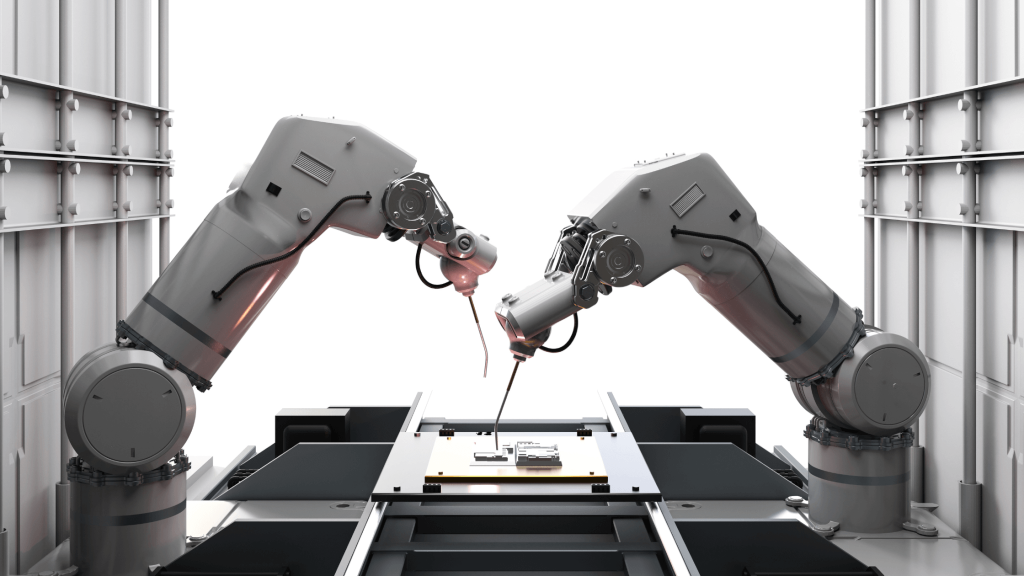

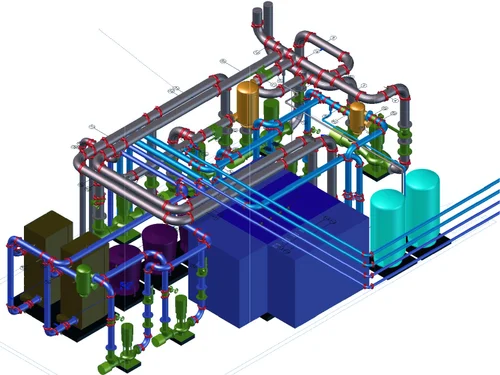

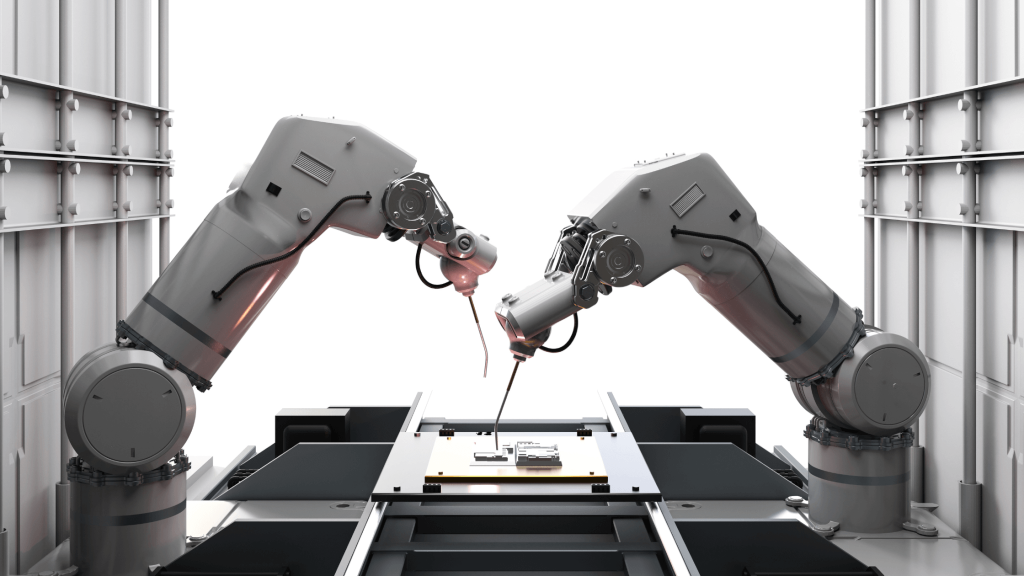

Industrial Automation & Custom Machinery

Design and development of automated manufacturing systems.

Custom-built machinery tailored to specific industry requirements.

Integration of robotics and smart technology to streamline production.

Optimized automation solutions to enhance efficiency and reduce downtime.

Contract Manufacturing & Supply

- Beyond design, PACECAD offers end-to-end manufacturing solutions, including CNC machining, 3D printing, sheet metal fabrication, and assembly supply.

- CNC Machining (Milling, Turning, Laser Cutting) 3D Printing & Rapid Prototyping Sheet.

Services We Offer

Product Design & Development

- We turn ideas into manufacturable designs with advanced 3D CAD modeling, reverse engineering, and prototype development. Whether it’s an early-stage concept or an improvement to an existing product, we ensure feasibility and functionality.

- 3D CAD Modeling (SolidWorks, AutoCAD, Fusion 360) Conceptual Design & Development

- Reverse Engineering & Design Optimization Prototyping & Feasibility Studies

Manufacturing Support & Drafting

- Manufacturing requires precise documentation and specifications. We provide high-quality 2D manufacturing drawings, GD&T, and BOM preparation, ensuring smooth production workflows.

- 2D Drafting & Manufacturing Drawings GD&T Application for Tolerancing BOM

- Preparation & Part Numbering Sheet Metal, Plastic, and CNC Machining Designs

Finite Element Analysis (FEA) & Simulation

- Structural integrity and performance validation are key to product success. Our advanced FEA simulations help identify weaknesses, optimize designs, and enhance durability.

- Static Structural Analysis – Strength and load-bearing assessments Thermal Analysis – Heat transfer simulations for optimal performance Vibrational & Modal Analysis – Ensuring stability under dynamic conditions Failure Analysis & Design Optimization

CAD Design & 3D Modeling

Comprehensive 2D and 3D CAD modeling for precision engineering.

Concept development with detailed technical drawings and documentation.

Design optimization to enhance efficiency, performance, and manufacturability.

Assembly modeling and interference analysis to ensure seamless integration.

Finite Element Analysis (FEA) & Computational Fluid Dynamics (CFD)

Structural analysis to assess stress, strain, and load-bearing capacity.

Thermal and dynamic simulations to ensure product reliability.

Fluid flow analysis (CFD) for aerodynamics and heat transfer optimization.

Failure prediction modeling to enhance safety and performance.

CNC Machining & Precision Manufacturing

High-precision CNC milling, turning, and grinding for complex geometries.

Prototyping to full-scale production with scalable manufacturing solutions.

Material selection expertise for durability and lightweight engineering.

Stringent quality control ensuring dimensional accuracy and consistency.

Prototyping & Product Development

Rapid prototyping using 3D printing, CNC machining, and injection molding.

Functional and ergonomic testing for performance validation.

Iterative design refinement for enhanced product efficiency.

End-to-end product development support, from concept to production.

Reverse Engineering & Legacy Part Digitization

High-precision 3D scanning and CAD modeling for component replication.

Digitization of obsolete parts for modern manufacturing applications.

Performance enhancement of existing designs through engineering analysis.

Seamless integration of reverse-engineered components into new product lines.

Industrial Automation & Custom Machinery

Design and development of automated manufacturing systems.

Custom-built machinery tailored to specific industry requirements.

Integration of robotics and smart technology to streamline production.

Optimized automation solutions to enhance efficiency and reduce downtime.

Contract Manufacturing & Supply

- Beyond design, PACECAD offers end-to-end manufacturing solutions, including CNC machining, 3D printing, sheet metal fabrication, and assembly supply.

- CNC Machining (Milling, Turning, Laser Cutting) 3D Printing & Rapid Prototyping Sheet.